Industries We Serve | Products | Solutions | Resources | Blogs | About Us | Contact Us

2000+ Happy Customers

String Wound Cartridge Filter

A string-wound filter cartridge is a depth filter made by tightly weaving yarn around a core in a honeycomb pattern. This unique structure creates layers of filtration, ensuring efficient removal of impurities and consistent performance.

String-wound filters are highly versatile depth filtration cartridges designed to effectively remove suspended particles, sediments, dirt, rust, and contaminants from liquids. Made by winding fibers in an overlapping pattern around a central core, these filters provide exceptional filtration efficiency while maintaining structural integrity, unlike surface filters that rely on a thin membrane to block contaminants, string-wound filters utilize their depth structure to trap particles at multiple levels. This makes them ideal for processes requiring thorough filtration without significant pressure loss

String-wound filters are a part of pre-filtration and fine particle removal processes across industries. Their combination of cost-efficiency, customizability, and high contaminant retention has made them a trusted choice in water and wastewater treatment(CETP, WTP, ETP, STP, Desalination and ZLD), chemical production, surface coating and plating applications and many other critical applications.

Gopani’s string-wound filters are made to meet the standards of performance, durability, and cost-effectiveness. Our filters are trusted across industries from water treatment to oil and gas, food and beverage, desalination plants, pharmaceuticals and more. Gopani’s string-wound filters deliver precision filtration tailored to your needs.

Key Features:

- Customizable Micron Ratings: From 0.5 µm to 100 µm, made for your process needs.

- Flexible Material Options: Polypropylene, cotton, glass fiber, for different applications.

- Durable Core Materials: Available in polypropylene and stainless steel.

Upgrade Your Filtration Systems Today

Find retable filters that improve performance and save cost.

Choose the right one for your need today!

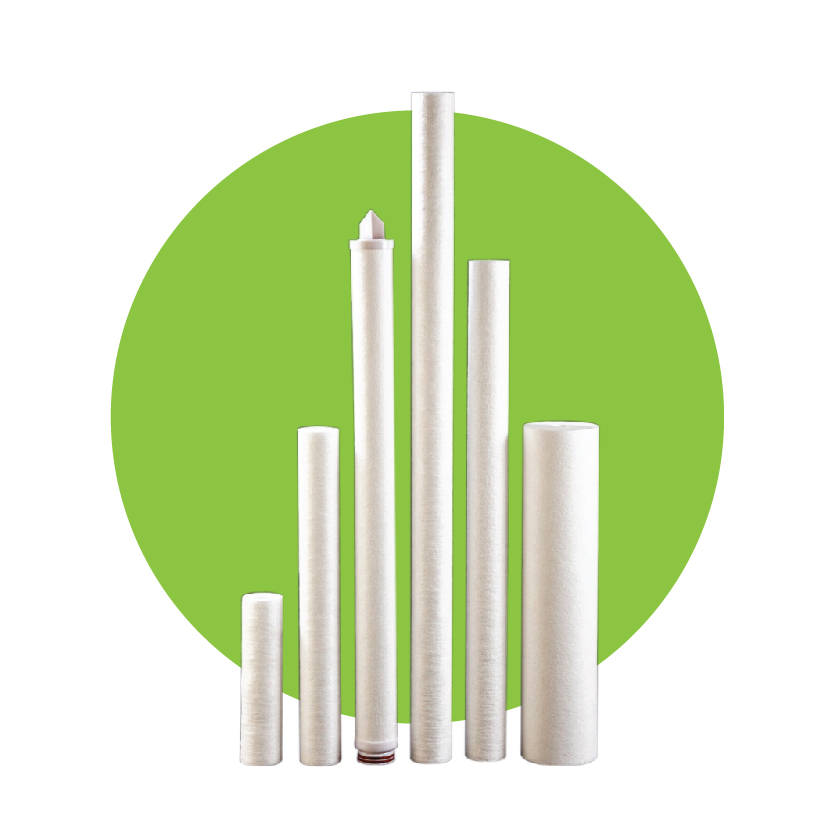

Range of String Wound Cartridge Filters For Diverse Applications

Clary Wound Extreme

Produced from activated carbon, these cylindrical blocks are meant for purification.

Applications: Ideal for food & beverage and high-temperature fluid filtration.

Clary Wound GF

Produced from activated carbon, these cylindrical blocks are meant for purification.

Applications: Ideal for food & beverage and high-temperature fluid filtration.

Clary Wound CPU

High flow cartridge filters for superior filtration

Applications: Ideal for food & beverage and high-temperature fluid filtration.

Customization

Gopani offers custom solutions to meet specific needs, including customized micron ratings, sizes, and material compatibility, ensuring optimal performance for every application.

Customized Filtration Solutions

Customised solutions for your filtration process with our string wound filters.

Our experts will help you find the solutions for your needs

Where Are String-Wound Filters Used?

Water Treatment and Desalination

The world is facing an acute water crisis, seawater desalination and clean water treatment are essential. String-wound filters are important for pre-filtration solutions in reverse osmosis (RO) systems. By removing sediments, silt, and particulate matter, these filters reduce membrane fouling, ensuring cleaner water output and extending membrane life.

Did You Know?

- The global desalination market is projected to grow to $32 billion by 2027, driven by increasing water demand.

- Proper pre-filtration can extend RO membrane lifespan by up to 50%, reducing replacement/cleaning chemical costs and maintenance downtime.

Why Gopani Filters?

Gopani’s string-wound filters ensure >90% removal of suspended solids, safeguarding critical downstream RO systems and improving overall process efficiency.

Wastewater Treatment, Effluent treatment plant, Sewage treatment plant, and Common effluent treatment plant

Wastewater treatment plants face the challenge of removing solids and contaminants to meet environmental discharge standards or enable water reuse. Gopani’s filters help reduce Total Suspended Solids (TSS) efficiently, acting as a reliable pre-treatment option before biological and chemical treatment stages.

- The global wastewater treatment market is expected to reach $482 billion by 2030, with growing emphasis on sustainable water reuse.

- Implementing efficient filtration systems can reduce energy costs by 10-15% in wastewater treatment plants by optimizing downstream operations.

Why Gopani Filters?

Gopani filters are designed for high dirt-holding capacity, minimizing replacements and ensuring continuous, cost-effective operation.

Food and Beverage Industry

In food and beverage production, maintaining product purity and quality is critical. Gopani’s string-wound filters remove impurities like sediments, rust, and particulates without compromising taste, texture, or product integrity. They are widely used for:

- Clarification of fruit juices, wine, and milk.

- Purification of process water and clean-in-place (CIP) systems.

Key Stats

- The global food and beverage filtration market is projected to grow at a 6.5% CAGR, reaching $1.2 billion by 2026.

- String-wound filters ensure consistent filtration performance, reducing production downtime and ensuring compliance with FDA and FSSAI standards for food-grade processing.

Why Gopani Filters?

Gopani’s filters offer desired filtration that are safe for food and beverage production, ensuring clean, compliant operations.

Oil and Gas Industry

Oil field operations rely on filtration systems to remove contaminants from well fluids, fuels, and lubricants. String-wound filters helps in preventing equipment damage, reduce maintenance costs, and improve operational efficiency.

Industry Stats

- The oil and gas filtration market is valued at $6.1 billion and is projected to grow due to increasing demand for cleaner fuel.

- Contaminants in process fluids contribute to 60% of equipment failures in oil and gas operations.

Why Gopani Filters?

Gopani filters provide high-temperature resistance and durability for challenging oil field applications.

Power Generation

Power plants require high-quality feed water for boilers, turbines, and cooling systems. Even small impurities can cause scaling and corrosion, leading to efficiency loss and expensive repairs. String-wound filters are critical for pre-treating boiler feed water and protecting sensitive equipment.

Relevant Data

- Scaling caused by untreated impurities can reduce boiler efficiency by up to 20%, increasing energy costs.

- Proper water pre-filtration in power plants can extend equipment lifespan by 25-30%.

- Clary Wound CPU: Synthetic fibers for precision filtration, ideal for microelectronics, pharmaceuticals, and power plant applications to handle contaminants like CRUD (Chalk River Unidentified Deposits).

Why Gopani Filters?

Gopani’s string-wound filters ensure precise particle removal and steady flow rates, preventing downtime and saving energy costs.

Pharmaceutical and Healthcare

Pharmaceutical industries demand high-purity water for drug formulation, laboratory applications, and sterile processes. Contaminants like particulates, rust, and bacteria can compromise product quality and safety. Gopani’s string-wound filters offer exceptional purity and reliability.

Key Insights

- The pharmaceutical filtration market is expected to grow to $10.4 billion by 2027, driven by stringent purity standards.

- Contaminant-free water reduces the risk of batch rejection, saving up to 40% on production losses.

Electronics and Semiconductor Manufacturing

In the semiconductor industry, ultra-pure water (UPW) is essential for cleaning, etching, and manufacturing processes. Even microscopic contaminants can lead to product defects and operational losses. Gopani’s string-wound filters deliver precision filtration for ultrapure water systems.

Key Insights

- Semiconductor production requires 99.999% pure water for cleaning processes.

- Filtration failures can cause up to $200,000 in losses per production batch in advanced semiconductor manufacturing.

Why Gopani Filters?

Gopani filters ensure reliable filtration of plating baths, providing the purity essential for defect-free production.

Conclusion

We understand how critical effective filtration is to your processes. That’s why we’ve designed our string-wound filters to deliver unmatched performance, reliability, and cost savings. Whether you need cleaner water, higher-quality products, or better protection for your equipment, our filters are tailored to meet your exact needs.

Choose Gopani for filters that last longer, work harder, and give you peace of mind. Let’s optimize your filtration together and ensure your operations run smoothly every day.

Customized Filtration Solutions Used Application

Customised solutions for your filtration process with our string wound filters.

Our experts will help you find the solutions for your needs

How Are String Wound Cartridge Filters Made?

Every string-wound filter begins with a sturdy, perforated central core. The core serves as the backbone of the filter, providing stability and supporting the yarn or fiber layers. Gopani’s filters utilize core materials like polypropylene for chemical compatibility and stainless steel for high-pressure applications, depending on the specific process requirements.

Fiber Material

The “string” or yarn used in string-wound filters plays a critical role in their performance. Gopani uses premium-grade fibers, including:

- Polypropylene: Ideal for water treatment, chemicals, and corrosive environments.

- Cotton: Suited for food-grade and oil-based applications.

- Glass Fiber: A durable option for high-temperature filtration processes.

- Polyesters : Polyester is a versatile synthetic fiber that offers good resistance to chemicals and high temperatures.

- Nylon : Nylon is a synthetic polymer known for its excellent mechanical strength and chemical resistance.

Each material is selected to match its target application, ensuring optimal contaminant removal and product lifespan.

Fiber to Yarn Process

The yarns used in these filters are produced using techniques such as friction spinning, which convert fibers into yarns with specific structural characteristics. Friction spinning involves the high-speed rotation of drums to twist and bind fibers into a yarn. This method creates a yarn with an airy or fluffy texture, which directly impacts its filtration properties.

The fluffiness increases the void volume within the yarn structure. Void volume refers to the spaces between individual fibers within the yarn. A higher void volume enhances the yarn’s ability to capture and retain particles, as the increased surface area and gaps allow contaminants to be trapped effectively. This structure improves filtration efficiency without significantly hindering the flow of air or liquids through the filter media.

Moreover, yarns produced through friction spinning demonstrate improved resilience and flexibility, enabling the filter to perform consistently under varying operational pressures and conditions. These properties are critical for applications requiring precise and efficient filtration.

Winding Process

Fibers are wound tightly and in a gradient around the core in a controlled spiral/honeycomb pattern. This creates a graded density structure, where the outer layers capture larger particles, while the inner layers trap finer contaminants.

- Outer Layers: Capture coarse sediments.

- Inner Layers: Remove finer particles.

Micron Rating Customization

Gopani’s string-wound filters are manufactured with specific micron ratings, ranging from 0.5 micron to 100 microns. Whether your process requires removal of impurities or coarser contaminants, our filters can be tailored to meet those needs with precision.

Core of String Wound Cartridge Filters

The core is the central structural component of a string-wound filter cartridge. It serves as the foundation around which the filtration yarn or string is wound, providing strength and stability to the entire filter. The material of construction (MOC) of the core is critical, as it determines the filter’s durability, chemical compatibility, and temperature resistance. Selecting the right core material ensures optimal performance for specific filtration applications.

Basic Function of the core

The core serves several essential purposes:

- Structural Integrity: It provides strength to prevent the filter from collapsing under pressure.

- Chemical Resistance: Ensures the filter performs effectively in corrosive environments.

- Thermal Stability: Maintains functionality at high or low operating temperatures.

- Durability: Extends the operational life of the filter by resisting wear.

Materials of Construction (MOC) for String-Wound Filter Cores

Gopani’s string-wound filters are manufactured with specific micron ratings, ranging from 0.5 micron to 100 microns. Whether your process requires removal of impurities or coarser contaminants, our filters can be tailored to meet those needs with precision.

- Polypropylene Core

- Description: A lightweight, chemically inert material resistant to most acids, alkalis, and organic solvents.

- Purpose: Ideal for applications requiring compatibility with a wide range of liquids at moderate temperatures. Commonly used in water treatment, food and beverage, and pharmaceutical industries.

- Stainless Steel Core (SS304/SS316)

- Description: A lightweight, chemically inert material resistant to most acids, alkalis, and organic solvents.

- Purpose: Ideal for applications requiring compatibility with a wide range of liquids at moderate temperatures. Commonly used in water treatment, food and beverage, and pharmaceutical industries.

- Other Options

- CPVC / UPVC Cores

- PVDF Core

- PTFE Core

- Galvanised Iron Core

Customized Filtration Solutions Mad by Filter

Customised solutions for your filtration process with our string wound filters.

Our experts will help you find the solutions for your needs

How to Choose the Right Core for String Wound Cartridge Filters

Selecting the right core depends on several factors:

- Chemical Compatibility: Consider the liquid being filtered and its chemical properties. For acidic or alkaline fluids, polypropylene or stainless steel cores are ideal.

- Temperature Range: Assess the operating temperature of the application. Stainless steel is preferred for high-temperature environments, while polypropylene suffices for standard conditions.

- Pressure Requirements: For high-pressure applications, opt for materials like stainless steel or glass-reinforced polypropylene.

- Cost Constraints: Choose tinned steel or standard polypropylene cores for economical solutions in less aggressive environments.

By carefully evaluating these factors, you can ensure optimal performance, longevity, and cost-efficiency for your filtration system.

End Connections and Gaskets

End connections and gaskets ensure a secure fit between the filter cartridge and the housing, preventing leakage and maintaining process integrity. Common end caps include DOE (Double Open End), SOE (Single Open End), and customized fittings, while gaskets are typically made from elastomers like EPDM, silicone, or PTFE.

Importance and Function

End connections provide structural stability and compatibility with various filter housings, ensuring easy installation and replacement. Gaskets create a reliable seal, preventing bypass and ensuring that only filtered fluid passes through.

MOC of End Caps and Gaskets

- End Caps: Polypropylene, stainless steel, or PVC for compatibility with a range of chemicals and environments.

- Gaskets: Materials like silicone and PTFE are used for high-temperature and chemical-resistant applications, while EPDM is chosen for general-purpose use.

Customized Filtration Solutions

Customised solutions for your filtration process with our string wound filters.

Our experts will help you find the solutions for your needs

Why Choose Gopani’s String-Wound Filters?

We create filters you can trust. Using advanced manufacturing and high-quality materials, our string-wound filters are made for better performance, and cost effectiveness.

What Makes Gopani the Right Choice?

- Filtration Efficiency: Our filters capture more dirt and particles while keeping the flow smooth, thanks to their unique layered design.

- Customized solutions: We customize filters to fit your specific requirements, whether it’s micron size, core material, or application type.

- Cost-Effective: Longer-lasting filters mean fewer replacements, less maintenance, and big savings for your operations.

- Trusted Experts: With years of experience and clients across industries, Gopani is a name you can count on for quality filtration solutions.

Why Gopani Filters?

With 3 decades of experience in designing high-performance filtration solutions, Gopani ensures reliability and efficiency in industrial processes.

Industries We Serve

Our filters are widely used in industries such as water treatment, pharmaceuticals, chemicals, oil and gas, and food and beverage, meeting the most stringent quality standards.

5 Key USPs of Gopani String Wound Filter Cartridges

1. Graded Density Construction

Designed with precision, the graded density structure captures contaminants of varying sizes, ensuring efficient filtration and extended service life.

2. Wide Material choices for better Compatibility

Available in diverse materials such as polypropylene, cotton, and glass fiber, these filters cater to applications across industries like chemicals, oil & gas, food & beverage, and more.

3. Customization

Offering micron ratings from 1 to 100 microns and various cartridge lengths, Gopani ensures filters meet specific operational and process requirements.

4. Extended Lifespan

Engineered for durability, the filters maintain high performance even in challenging conditions, reducing replacement frequency and downtime.

5. Low Pressure Drop

Optimized design minimizes pressure loss, ensuring smooth flow rates and operational efficiency.

Benefits

- High Dirt Holding Capacity: Captures more contaminants, extending operational intervals.

- Cost-Efficiency: Reduces operational costs by minimizing replacements and downtime.

- Versatile Application: Suitable for industries such as pharmaceuticals, oil & gas, wastewater treatment, and food & beverage.

Customized Filtration Solutions

Customised solutions for your filtration process with our string wound filters.

Our experts will help you find the solutions for your needs

Frequently Asked Questions (FAQ)

- What is the lifespan of Gopani’s string-wound filters?

Ans: The lifespan of our filters depends on your specific application and operating conditions, but they are designed for maximum durability and efficiency. Regular monitoring will help you determine the right replacement schedule. It is very difficult to gauge life of the filter and give a generalised number for all applications. However we can help you determine the life of filters in your applications with some basic tests.

- What sizes and micron ratings are available?

Ans: We offer filters in a variety of lengths, diameters, and micron ratings—from 0.5 microns to 150 microns to suit different applications and requirements.

- How do I choose the right filter for my process?

Ans: Our experts can guide you based on your specific needs, such as the type of liquid, flow rate, contaminants, and operating conditions. Contact us for personalized recommendations.

- Can Gopani customize filters for unique applications?

Ans: Absolutely! We specialize in creating tailored filtration solutions, including custom micron ratings, core materials, and dimensions.

- What industries are Gopani filters used in?

Ans: Our filters are widely used in industries like water treatment, wastewater management, pharmaceuticals, oil and gas, food and beverage, and power generation.

- How do I maintain and replace the filters?

Ans: Gopani filters are easy to install and replace. Maintenance involves regular checks for pressure drop and flow rate. Our team can assist with best practices to maximize filter life.

Still Have Questions?

We’re here to help!

Reach out to us for more information or a personalized consultation.

Explore more About String-Wound Filters

Customized Filtration Solutions

Customised solutions for your filtration process with our string wound filters.

Our experts will help you find the solutions for your needs

How to Reach Us?

Get in Touch

104 Kashi Parekh Complex, Swastik Cross Road, B/h Bhagwati Chambers, C. G. Road, Navrangpura, Ahmedabad – 380009. Gujarat, India.

Ph: +91-706 901 8049

Quick Links:

- Oil and Gas

- Power Plant

- Chemical Industry

- Pharma Industry

- Food and Beverage

- Refineries and Petrochemicals

- Water and Wastewater Treatment

- Desalination

- Process and Utilities Water Treatment