What are filter bags for?

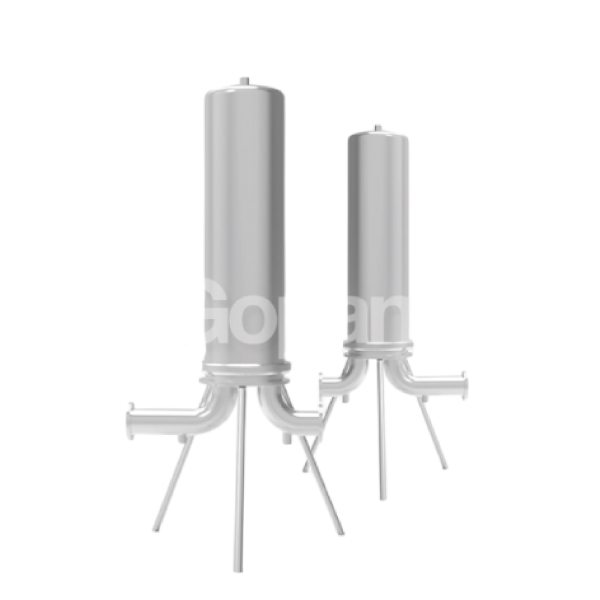

Filter bags are an integral part of bag filter systems, used to capture and remove solid particles from liquids or gases. They help reduce downstream contamination and improve process efficiency across industries like chemicals, food & beverage, pharmaceuticals, and water treatment.