Gopani has a modern state-of-art facility where glass fiber filter cartridges are manufactured in a highly controlled environment. The cartridge filter is manufactured using the highest quality yarn, suitable core material and sturdy end-caps. Every string wound glass fiber filter undergoes a thorough quality check before moving out of the facility. Gopani’s Clarywound GF cartridge filters are extremely resistant to corrosive liquids and aggressive chemicals. The filter works like a dream for applications involving high temperature exposure, reactive chemicals and corrosive liquids.

Standard – 0.55 ft2 / 10 inch length

Jumbo – 0.94 ft2 / 10 inch length

Gopani’s glass fibre filter cartridges are designed and manufactured for resistance to a wide range of chemical solutions.

Check out other string wound cartridge filter variants:

All Clarywound Cartridge Filters are:

• Customized to perfection based on application requirements

• Woven to offer a gradient depth for superior filtration

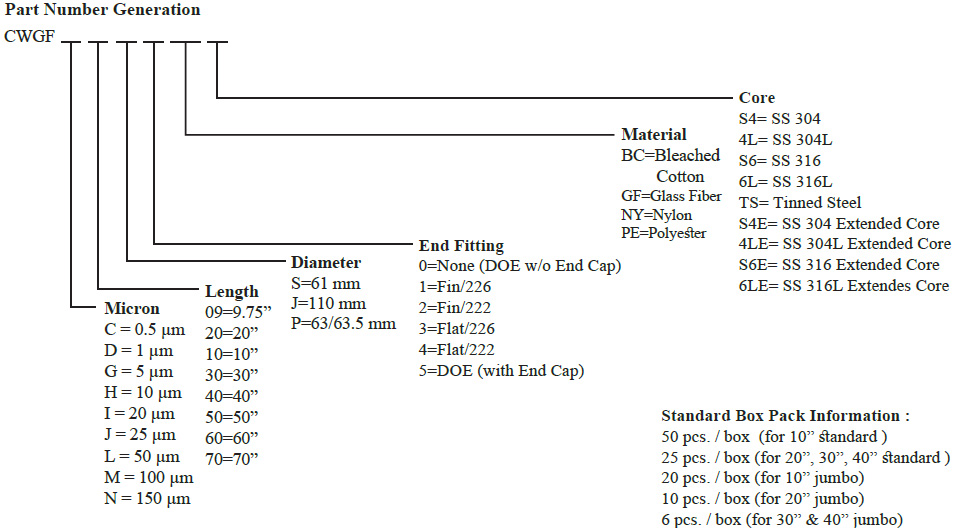

• Available in different length and material variants

• Designed to sustain low pressure drops and high flows

• 100% free from resin binders, lubricants, antistatic and release agents

All Clarywound cartridges are readily available for your convenience. We also offer scheduled delivery service to fulfill your annual requirement of filter cartridges.

These filter cartridges are produced solely from activated carbon and are also referred to as activated carbon blocks. Meticulously sourced superior quality coconut shell is uti...

Know MoreThese filter cartridges are produced solely from activated carbon and are also referred to as activated carbon blocks. Meticulously sourced superior quality coconut shell is uti...

Know MoreTalk to our Experts

All Clarywound cartridges are readily available for your convenience. We also offer scheduled delivery service to fulfill your annual requirement of filter cartridges.

Contact Us