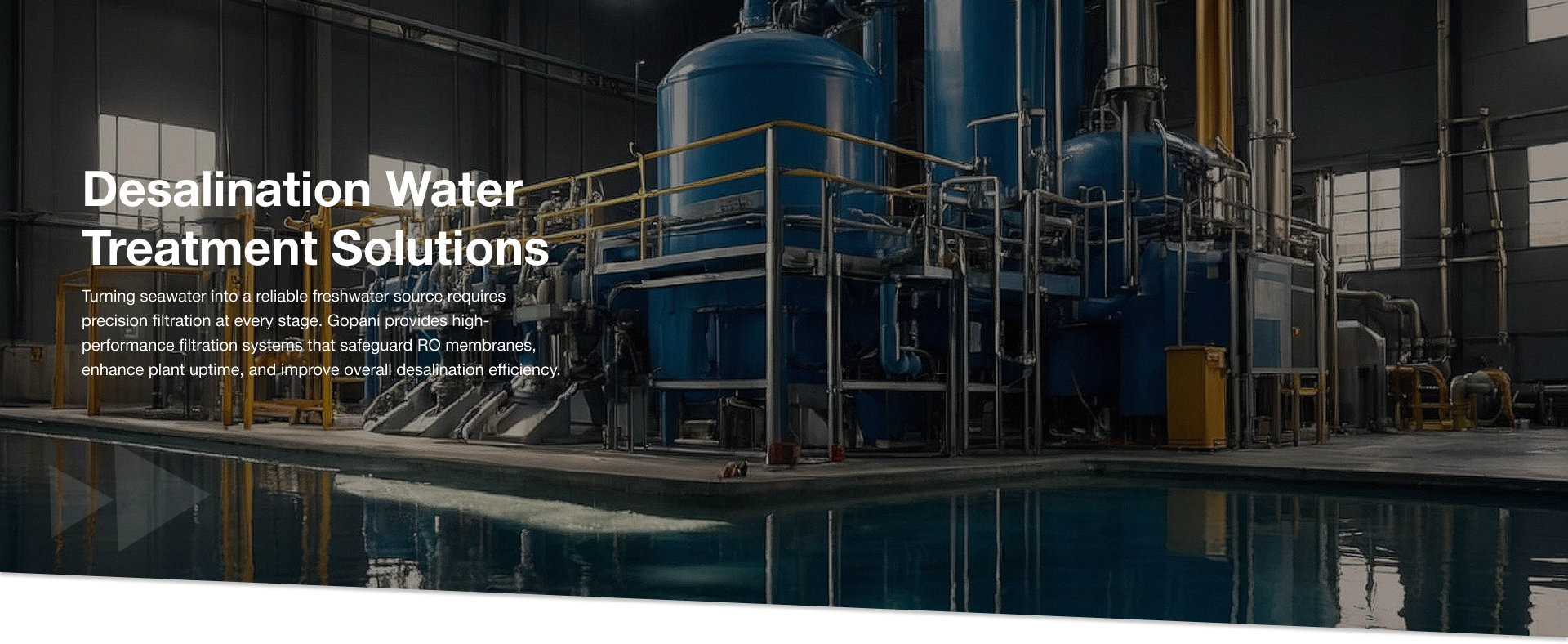

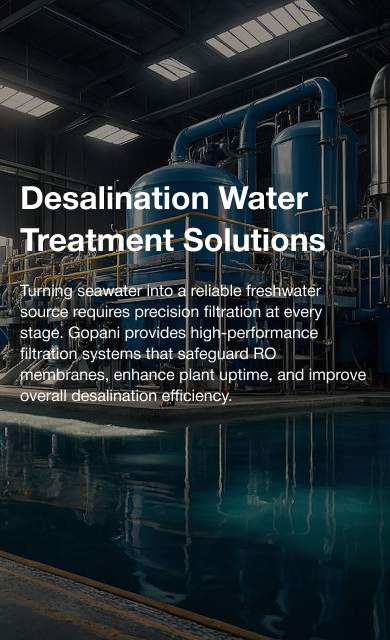

What is Desalination?

Desalination is the process of removing dissolved salts, minerals, and impurities from seawater or brackish water to produce water suitable for human, industrial, or agricultural use. It plays a vital role in addressing freshwater scarcity in coastal regions, islands, and arid zones.

With rainfall declining and global water demand rising, desalination has become a key solution for water security. Modern desalination systems rely on Reverse Osmosis (RO) technology, where high-pressure pumps force seawater through semi-permeable membranes that separate salts and contaminants from clean water.

The success and longevity of any desalination plant depend heavily on the efficiency of its filtration stages, particularly pre-filtration and membrane protection systems.

How Desalination Works

Intake and Pre-Treatment

Seawater or brackish water is drawn into the plant and passed through a series of filters to remove suspended solids, colloids, and organic matter. This protects downstream RO membranes from fouling and damage.

Reverse Osmosis Filtration

The pre-treated water is forced through RO membranes that block salts, bacteria, and impurities. The process produces two streams: freshwater for use and concentrated brine that is safely discharged.

Post-Treatment and Distribution

The treated water is mineral-balanced, disinfected, and distributed for consumption or industrial use.

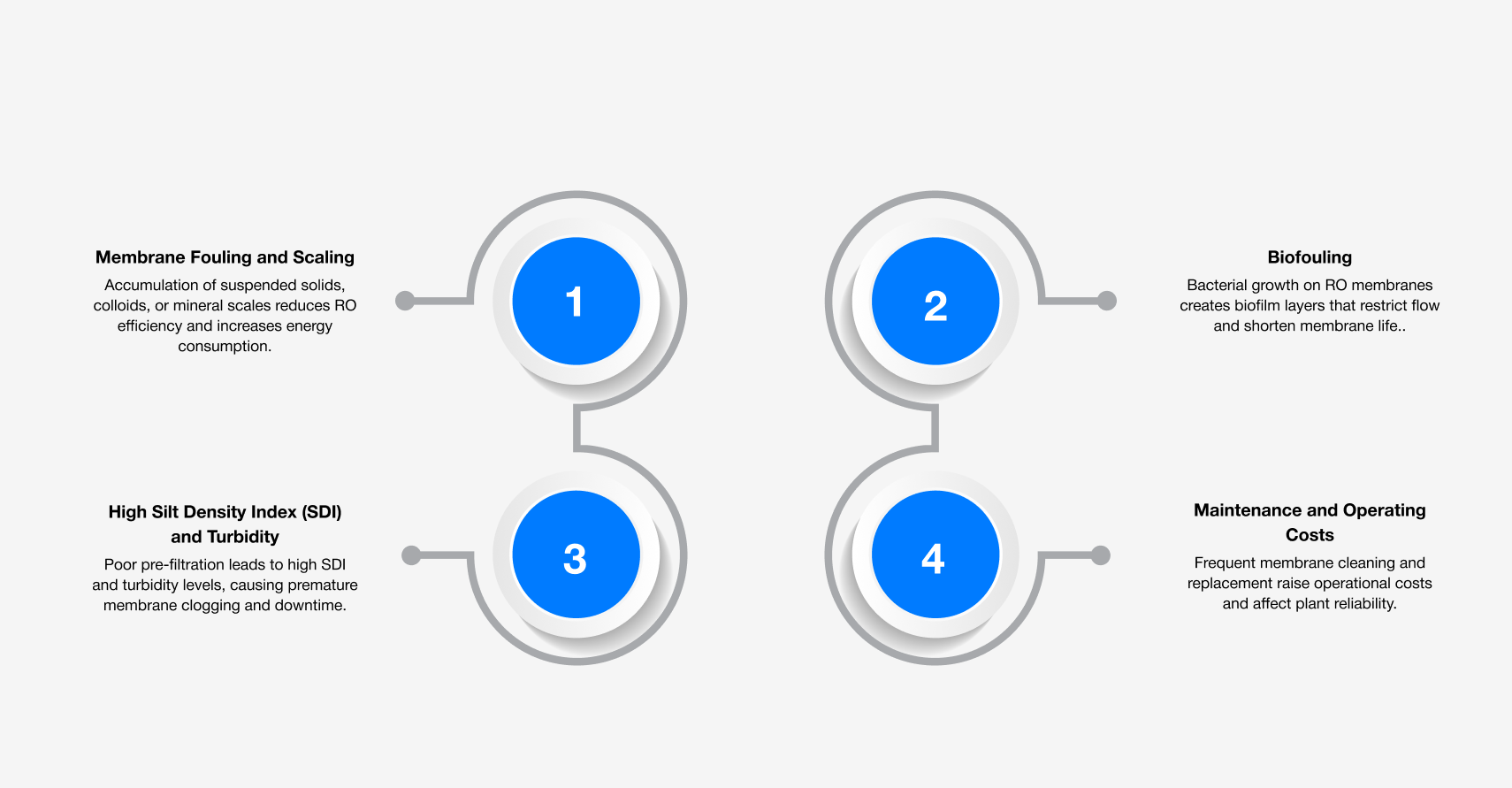

Key Challenges in Desalination

Key Challenges in Application

• Membrane Fouling and Scaling

Accumulation of suspended solids, colloids, or mineral scales reduces RO efficiency and increases energy consumption.

• Biofouling

Bacterial growth on RO membranes creates biofilm layers that restrict flow and shorten membrane life.

• High Silt Density Index (SDI) and Turbidity

Poor pre-filtration leads to high SDI and turbidity levels, causing premature membrane clogging and downtime.

• Maintenance and Operating Costs

Frequent membrane cleaning and replacement raise operational costs and affect plant reliability.

How Gopani Helps

Gopani delivers advanced filtration and pre-treatment systems engineered to enhance membrane performance and ensure long-term desalination efficiency.

Our product portfolio for desalination includes cartridge filters, filter housings, depth filters, and membrane protection solutions designed to handle varying water conditions and contamination levels.

Benefits of Gopani Filtration Solutions:

- Extends RO membrane life and stability

- Improves SDI and turbidity control

- Ensures consistent compliance with water quality standards

- Reduces fouling, scaling, and biofouling

- Enhances plant uptime and throughput

- Minimises operational and maintenance costs

Gopani’s Product Offerings for Desalination

Melt Blown Cartridge Filters

High-efficiency pre-filters for suspended solids and colloid removal

Stainless Steel Filter Housings

Durable housings built for high-pressure RO and seawater applications

FAQs

What are the main challenges in desalination?

High SDI, membrane fouling, biofouling, and high maintenance costs are common challenges affecting RO performance.

How does Gopani improve desalination efficiency?

By providing advanced pre-filtration and membrane protection systems that control turbidity, lower SDI, and prevent fouling.

What filters are used in desalination?

Melt-blown and pleated cartridge filters, depth filters, and 1-micron filters are widely used for desalination pre-treatment.